In the ever-evolving world of 3D printing, finding the best resin 3D printer can be as challenging as navigating a labyrinth. With a growing array of brands and features, it’s like trying to find a needle in a haystack. But don’t worry; we’re here to help you cut through the noise and find the ideal resin printer for your creative projects, whether you’re crafting miniatures, prototypes, or intricate models.

Understanding Resin 3D Printing

Before diving headfirst into picking the best resin 3d printer, let’s clarify what resin printing entails. Unlike the more common FDM (Fused Deposition Modeling) printers that use filament, resin printers use a liquid photopolymer that solidifies when exposed to UV light. This process, known as stereolithography (SLA) or Digital Light Processing (DLP), offers higher resolution and intricate detail compared to its FDM counterparts.

How Resin 3D Printers Work

Curious about how these machines conjure intricate designs from liquid resin? They rely on UV light to cure the resin layer by layer, creating detailed models from the ground up. An LCD screen, digital projector, or laser selectively exposes the resin to light based on your model’s cross-sectional layers, forming the desired shape with pinpoint precision.

Why Choose a Resin 3D Printer?

Wondering if a resin printer is the best choice for you? If you’re after ultra-fine details and smooth surface finishes, resin is the way to go. It’s perfect for highly detailed figurines, jewelry, dental models, and engineering prototypes that demand intricate detailing.

Choosing the Best Resin 3D Printer

Selecting the best resin 3d printer isn’t just about picking the fanciest model; it’s about finding one that matches your needs. Let’s break down the key factors to consider.

1. Resolution and Layer Height

The layer height of a resin 3D printer significantly impacts the final print’s quality. The layer height refers to the thickness of each individual layer that makes up the print, determining how detailed and refined the final product will be. Printers offering adjustable layer heights give you the flexibility to fine-tune quality versus speed. A printer capable of 25-50 microns is ideal for producing crisp, high-resolution models.

2. Print Speed

Balancing speed with quality is crucial. Some resin printers use monochrome LCD screens, which speed up curing time compared to older RGB screens. If time is of the essence and you’re working on a tight schedule, consider this feature to minimize printing time without sacrificing detail.

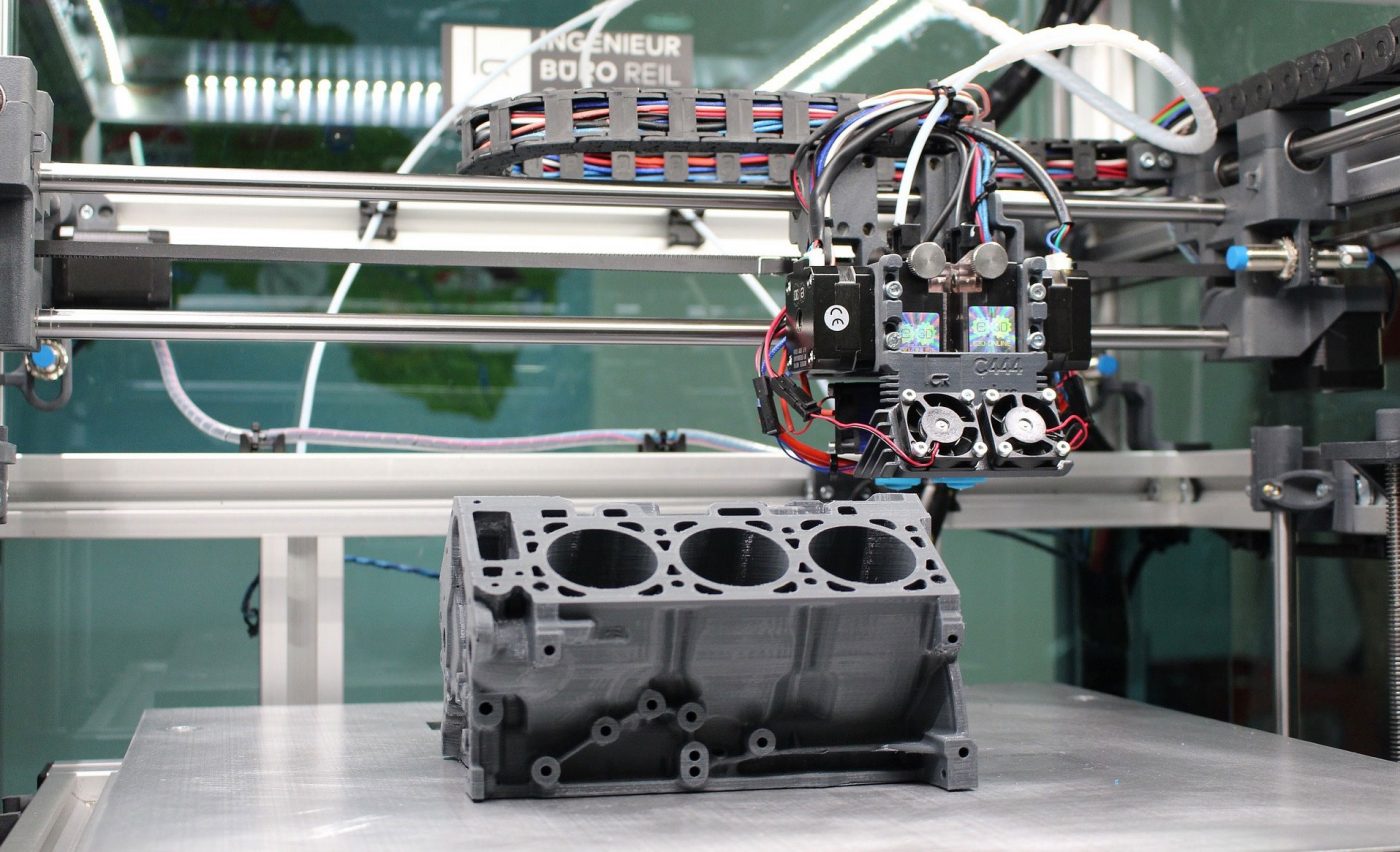

3. Build Volume

How large or small are your typical projects? The build volume determines the maximum size you can print in one go. Larger build volumes allow for bigger models or multiple smaller ones at once, which is useful if you’re batch-producing items or working on larger architectural or engineering prototypes.

4. Resin Compatibility

Not all resins are created equal. Some printers only work with proprietary resins, while others accept a broader range. If flexibility is important to you, opt for a printer with open resin compatibility. This way, you can experiment with specialty resins like flexible, heat-resistant, or dental-grade types.

5. Software and User Interface

A user-friendly interface makes all the difference. Look for printers that offer intuitive slicing software, preconfigured print settings, and the ability to easily upload models. Advanced software may also come with features like model optimization and repair, ensuring smoother prints.

6. Price and Budget

Like with any tech purchase, your budget will influence your choice. While premium printers offer top-notch features, plenty of budget-friendly options still deliver impressive quality. Balance your desired specifications with the available price range, and consider future upgrade paths as your needs evolve.

Additional Features to Consider

Beyond the main criteria, a few extra features could elevate your printing experience.

1. Connectivity Options

Does the printer offer Wi-Fi, Ethernet, or USB connectivity? If you’re part of a larger team or production line, seamless file transfer and remote monitoring can boost productivity.

2. Print Bed and Supports

A sturdy print bed minimizes calibration issues and ensures successful prints. Look for printers with easy-to-level beds or auto-leveling features. Additionally, consider how the printer handles support structures for overhangs and complex models.

3. Post-Processing

Does the printer come with or support post-processing equipment like wash stations and curing chambers? Properly curing prints after they’ve been cleaned ensures durability and minimizes any residual tackiness.

Top Picks for the Best Resin 3D Printer

Ready for some specific recommendations? Here are a few standout choices across different categories.

1. Best Overall: Phrozen Sonic Mini 4K

Phrozen’s Sonic Mini 4K is widely regarded as one of the best resin 3d printers. Offering a 4K resolution at an accessible price, it’s perfect for hobbyists and professionals alike. Its monochrome screen speeds up printing and ensures durability.

2. Best Budget-Friendly Option: Elegoo Mars 2 Pro

Elegoo’s Mars 2 Pro is a favorite for those seeking high quality on a budget. It delivers consistent performance with a 2K monochrome screen and open resin compatibility. It’s often praised for its reliability and ease of use, making it a solid choice for beginners.

3. Best Large-Scale Printer: Anycubic Photon Mono X

Need a larger build volume? The Anycubic Photon Mono X has you covered. Its generous build area and fast monochrome screen make it an excellent choice for sizable projects. It is perfect for printing larger models or producing multiple smaller items simultaneously.

4. Best Professional Model: Formlabs Form 3

Formlabs has long been a leader in professional-grade resin 3D printers, and the Form 3 continues this legacy. Its proprietary Low Force Stereolithography (LFS) technology ensures exceptional accuracy and smooth finishes. Its ecosystem of high-quality proprietary resins caters to different professional fields, from engineering to dentistry.

5. Best for High Resolution: EPAX E10 5K

If high resolution is a must, consider the EPAX E10 5K. Its 5K resolution provides unparalleled detail, and it’s compatible with a broad range of resins. This makes it ideal for those producing ultra-fine, detailed prints where precision is crucial, such as in jewelry design or miniature making.

6. Up-and-Coming Contenders: Pursa SL1S and Longer Orange 30

Two relatively new but rapidly rising stars are the Prusa SL1S and Longer Orange 30. The SL1S builds on Prusa’s reputation for user-friendly, reliable machines, while the Orange 30 offers exceptional print quality and open resin compatibility at a competitive price point.

Safety and Maintenance Tips for Resin Printing

Working with resin requires care, as it can be messy and toxic when uncured. Here are some tips:

- Wear Protective Gear:

Gloves and safety glasses are a must when handling liquid resin to avoid skin irritation or eye contact. Long-sleeved clothing can also prevent accidental spills from coming into direct contact with your skin. - Proper Ventilation:

Always use your printer in a well-ventilated area to minimize exposure to fumes. Uncured resin emits VOCs (volatile organic compounds), which can cause headaches or dizziness if inhaled over prolonged periods. - Regular Cleaning:

Clean your printer after each use to prevent resin buildup and prolong its lifespan. Make sure to carefully clean the print bed, the resin vat, and any other components that come into contact with the resin. - Filter and Store Resin Properly:

Use a filter when pouring resin back into its container to remove impurities. Properly label and store resin away from direct sunlight to prevent premature curing. - Disposal of Waste:

Dispose of waste resin or contaminated paper towels following local environmental guidelines. Resin that has been exposed to UV light should be fully cured before disposal.

Print Troubleshooting: Common Issues and Solutions

Like any technology, resin 3D printers can encounter problems.

Here are a few common issues and how to fix them:

- Failed Prints Failed prints can occur due to improper leveling, insufficient resin, or a clogged build plate. Regularly calibrate the build plate and ensure there’s enough resin in the vat before starting. If prints continue to fail, check for obstructions or contamination in the resin vat.

- Warping and Shrinkage Warping or shrinkage can happen due to over-curing or rapid temperature changes. Ensure the print isn’t exposed to direct heat sources and follow recommended curing times.

- Uneven or Uncured Layers Uneven or uncured layers often indicate an issue with the light source or exposure settings. Check that the light source is functioning correctly, and adjust the exposure times to match the resin type.

- Layer Separation Layer separation is a sign that the print isn’t adhering properly between layers. Double-check the layer heights and ensure that the resin isn’t expired or contaminated.

Advanced Printing Techniques: Getting the Most Out of Your Resin Printer

Once you’re familiar with the basics of resin printing, consider expanding your repertoire with these advanced techniques.

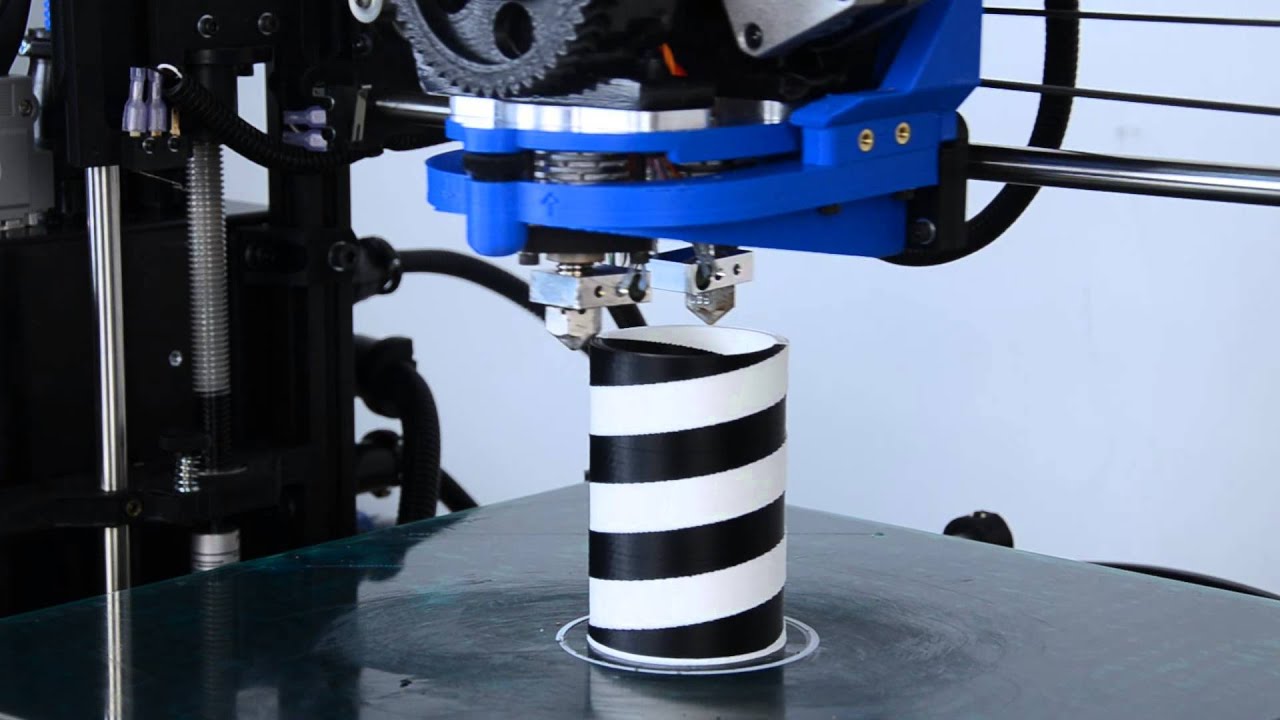

1. Multi-Material Printing

Some resin printers allow for multi-material printing by switching resins mid-print or incorporating different support structures. This technique is useful for creating models that need flexible hinges or distinct color zones.

2. Hollow Printing and Drainage Holes

Hollow models use less resin and reduce curing time. If printing hollow models, be sure to add drainage holes to prevent resin pooling inside the model and optimize post-processing.

3. Fine-Tuning Supports

Support structures can leave marks or require post-processing. Adjusting the density, size, and contact points of supports minimizes these marks and makes removal easier.

4. Micro Details and Miniatures

Printing ultra-fine details like those on miniatures requires specialized settings. Reduce the layer height to 25-35 microns and fine-tune exposure times to capture every intricate feature.

The Post-Processing Phase: Cleaning, Curing, and Finishing

Post-processing is a crucial step that ensures your printed model looks its best. Here’s a quick guide:

1. Cleaning the Print

After printing, rinse the model in isopropyl alcohol to remove uncured resin. Use a soft brush to get into crevices, and make sure to wear gloves.

2. Curing the Model

Curing the model under UV light hardens it fully and gives it a smooth finish. Some printers come with curing stations, but a portable UV lamp or even sunlight can work for smaller models.

3. Removing Supports

Gently remove supports using flush cutters or other fine tools. Be careful not to damage delicate features when cutting close to the model.

4. Sanding and Painting

Sand any rough edges with fine-grit sandpaper. If you’re planning to paint, prime the model first to ensure the paint adheres well.

Conclusion: Finding Your Perfect Resin Printer

Finding the best resin 3d printer boils down to understanding your specific needs and matching them with a printer’s features. Whether you’re a hobbyist looking to print your next tabletop miniature or a professional needing high-resolution prototypes, there’s a resin printer out there for you. Make sure to prioritize features that align with your unique creative or production goals and keep an eye on emerging trends in this rapidly advancing field.

Frequently Asked Questions (FAQs)

1. What kind of resin should I use for my 3D printer?

It depends on your application. Standard resins are versatile, while specialty resins offer specific benefits like flexibility, heat resistance, or dental-grade quality. Consider the end use of your model and select a resin type that best meets those needs.

2. How long does it take to print with a resin 3D printer?

Printing times vary based on the printer’s speed and the model’s complexity. Expect a few hours for most models, but high-speed monochrome screens can reduce this. Keep in mind that post-processing like cleaning and curing will add extra time.

3. Are resin 3D prints safe for food contact?

No, most resins are not food-safe. Even if cured, residual chemicals can pose a health risk. If food contact is necessary, consider FDM printing with food-grade filament instead.

4. Can I print multiple models simultaneously?

Yes, as long as they fit within the build volume. Slicing software can help arrange them optimally on the build plate. Make sure the models don’t overlap or interfere with each other’s supports.

5. Do resin 3D printers need calibration?

Yes, regular calibration of the build plate is crucial for accurate printing. Most printers offer straightforward leveling procedures. Additionally, periodically clean and check the light source, screen, or laser for optimal performance.