Introduction: The Rise of the Dual Extruder 3D Printer

In the dynamic sphere of technological advancements, the dual extruder 3D printer emerges as a pivotal innovation, reshaping the landscape of manufacturing and prototyping. This remarkable tool not only accelerates production processes but also significantly expands the creative boundaries for professionals and enthusiasts alike. But what exactly propels these printers into the spotlight of modern manufacturing?

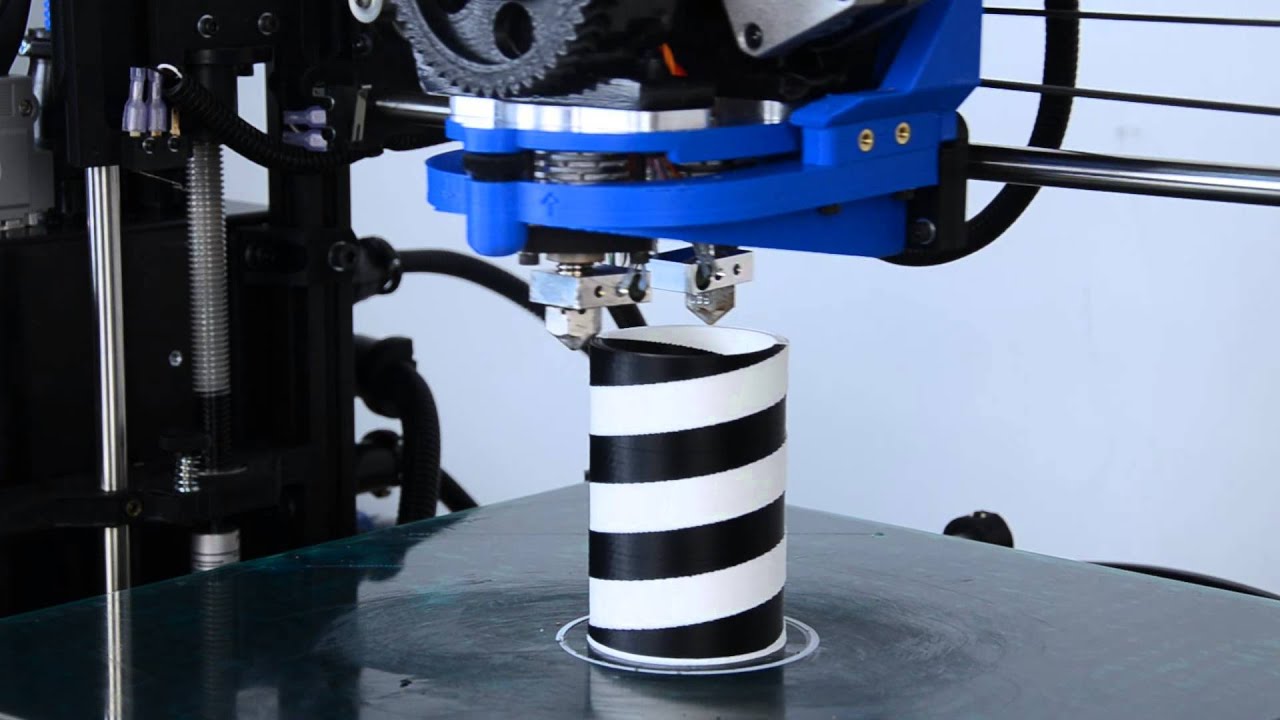

Understanding the Dual Extruder 3D Printer

A dual extruder 3D printer operates with two independent print heads, enabling it to simultaneously print with two different materials or colors. This dual capability enhances the printer’s efficiency and broadens the scope of projects it can handle, from intricate multi-color designs to complex models requiring support structures.

Advantages of Dual Extrusion Technology

The dual extruder setup offers several compelling benefits:

- Multi-Material Capability: Print complex models using structurally different materials, such as combining rigid and flexible filaments.

- Enhanced Color Possibilities: Create vibrant and detailed models without the need for painting, by using different colored filaments.

- Efficient Production: Simultaneously printing with two materials reduces the overall print time and the need for post-processing.

- Complex Designs Made Simple: Easily print intricate designs with support structures that dissolve or break away without residue.

Versatility Across Industries

The application of dual extruder printers spans various sectors:

- Healthcare: Produce customized prosthetics and models for surgical planning.

- Automotive: Fabricate parts with complex designs and tailored properties.

- Education: Enhance learning through tactile teaching aids and complex model creation.

- Fashion: Innovate with wearable fabrics and accessories that blend different materials.

Key Specifications to Consider when using a Dual Extruder 3D Printer

Choosing a dual extruder 3D printer involves several critical considerations:

- Print Resolution: Higher resolution printers can produce finer details, essential for intricate designs.

- Build Volume: Larger build volumes allow for printing bigger or multiple pieces simultaneously.

- Material Compatibility: Ensure the printer supports the types of materials required for your projects, such as PLA, ABS, PETG, and more.

Material Compatibility and Uses when using a Dual Extruder 3D Printer

Exploring the materials compatible with dual extruder printers reveals their adaptability:

- PLA and ABS: Popular for their ease of use and strength, suitable for a wide range of applications.

- Soluble Supports: Materials like PVA are ideal for creating support structures that dissolve in water, leaving a clean finish.

- Flexible Filaments: Use materials like TPU to add flexibility to parts, which is invaluable for custom gaskets or wearable items.

Impact on Print Speed and Quality when using a Dual Extruder 3D Printer

Dual extruders can impact print speed and quality in various ways:

- Increased Speed: Printing with two materials simultaneously can halve the production time for multi-material items.

- Quality Considerations: Balancing speed with quality is crucial, as higher speeds can sometimes reduce the detail in the final product.

Ease of Use for All Skill Levels

Modern dual extruder printers are designed with user-friendly interfaces, making them accessible to both beginners and experienced users. Features like touchscreen controls, intuitive software, and automated calibration help streamline the printing process.

Cost Analysis: Is It Worth the Investment?

While dual extruder printers are typically more expensive than their single extruder counterparts, the investment may be justified by the increased capabilities and efficiency. For businesses or serious hobbyists, the ability to produce complex, multi-material prints can significantly enhance product offerings and creative possibilities.

Customization and Flexibility: The Creative Benefits

The customization possibilities with dual extruder printers are nearly limitless. Users can experiment with different material combinations, intricate geometries, and varied color schemes to create unique, tailored products or prototypes.

Anticipating Future Trends in Dual Extrusion

The future of dual extruder 3D printing looks bright, with ongoing advancements in material science and extrusion technology. We might soon see even more versatile materials and improved print heads that offer finer detail and greater speed.

Navigating Common Challenges

Despite their advantages, dual extruder printers come with challenges such as oozing from idle nozzles, material compatibility issues, and complex setup processes. Solutions involve regular maintenance, using high-quality filaments, and selecting printers with robust support and community forums for troubleshooting tips.

Real-World User Experiences

Case studies from various sectors illustrate the transformative impact of dual extruder printers:

- A Medical Success Story: A hospital uses a dual extruder to create detailed anatomical models for surgical preparation, significantly improving outcomes.

- An Automotive Innovation: An auto manufacturer prototypes new car parts, reducing time-to-market and increasing customization.

Selecting the Perfect Printer: A Buyer’s Guide

When choosing a dual extruder 3D printer, consider your specific needs:

- Evaluate Your Requirements: Assess the types of projects you plan to undertake.

- Compare Features: Look at different models and their features within your budget.

- Read Reviews and User Feedback: Gain insights from other users to understand the printer’s performance in real-world settings.

Conclusion: Embracing the Dual Extruder 3D Printer

The dual extruder 3D printer offers a potent combination of efficiency, versatility, and creativity. Whether you aim to push the boundaries of design in your field or simply bring your imaginative concepts to life, these printers can be an invaluable asset.

FAQs About Dual Extruder 3D Printers

- What makes a dual extruder 3D printer different from a single extruder printer? Dual extruders allow simultaneous printing with two materials or colors, enhancing the complexity and detail of prints.

- Can dual extruder 3D printers use any type of material? While not all materials are compatible, many dual extruders can handle a variety of materials, including PLA, ABS, PVA, and others.

- Are dual extruder 3D printers more expensive than single extruder models? Yes, due to their increased capabilities, dual extruders are often more expensive.

- Is it difficult to operate a dual extruder 3D printer? These printers are more complex, but many are designed with features that simplify operation.

- What should I look for when choosing a dual extruder 3D printer? Consider factors like material compatibility, print quality, speed, user interface, and overall cost to ensure it meets your specific needs.

Conclusion:

With this comprehensive insight into dual extruder 3D printers, you are well-equipped to decide if this technology fits your creative or professional goals. Embrace the possibilities and watch your projects transform with the power of dual extrusion technology.