Introduction: Unveiling the Power of a 3D Printer That Prints Metal

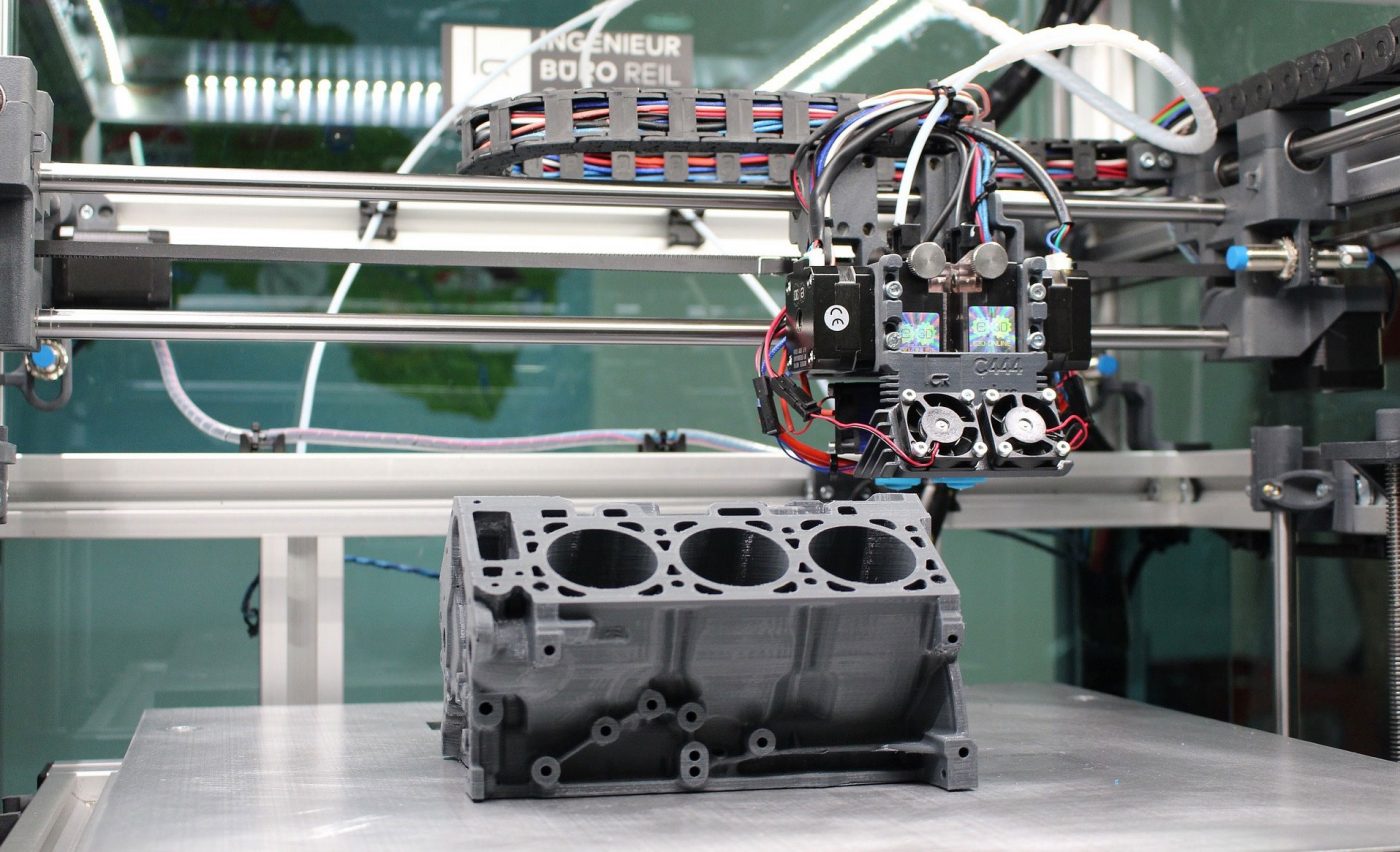

Metal 3D printing is transforming industries, from aerospace to automotive and healthcare. A 3d printer that prints metal not only innovates but also revolutionizes how we build and design complex components. Let’s explore how these printers work, their benefits, applications, and what future developments we might anticipate.

What is a Metal 3D Printer?

Metal 3D printing, also known as metal additive manufacturing, is a technology that builds three-dimensional objects by adding layer-upon-layer of material. These printers use metals such as titanium, stainless steel, and aluminum to produce highly detailed and complex structures.

How Does a Metal 3D Printer Work?

The process involves several steps:

- Design: Everything starts with a digital design file.

- Preparation: The machine prepares the metal material, usually in powder form.

- Printing: The printer uses a laser or electron beam to melt and fuse the metal powder.

- Cooling: The object cools and solidifies.

- Post-processing: This includes removal from the build plate and surface finishing.

Benefits of Using a 3D Printer That Prints Metal

- Complexity for Free: The cost of creating complex shapes is virtually the same as simple ones.

- Lightweighting: Parts can be made lighter without compromising strength.

- Reduced Waste: Metal additive manufacturing is more material-efficient.

- Faster Prototyping: Speeds up the development cycle of new products.

The Main Technologies Behind Metal 3D Printing

There are several key technologies used in metal 3D printing:

- Direct Metal Laser Sintering (DMLS): This is the most common technique.

- Electron Beam Melting (EBM): Uses an electron beam instead of a laser.

- Binder Jetting: Metal powder is bound together using a liquid binder.

Materials Used in Metal 3D Printing

Common materials include:

- Titanium: Known for its strength and light weight.

- Stainless Steel: Popular for its versatility.

- Nickel Alloys: High-temperature resistance makes them ideal for aerospace.

Applications of a 3D Printer That Prints Metal

Metal 3D printers are used in various sectors:

- Aerospace: For lightweight, high-strength structures.

- Automotive: For complex parts that reduce vehicle weight.

- Medical: For customized implants and surgical tools.

Design Considerations for Metal 3D Printing

When designing for metal 3D printing, consider:

- Orientation: Placement affects the strength and finish of a part.

- Supports: Necessary for overhanging structures.

- Layer Thickness: Impacts the surface quality and print time.

Challenges and Limitations

Despite its potential, there are challenges:

- Cost: High initial investment for machines and materials.

- Speed: Slower compared to other manufacturing methods.

- Size Limitations: Most printers have a restricted build volume.

Recent Innovations in Metal 3D Printing

Advancements continue to enhance capabilities and reduce costs:

- New Materials: Introduction of cheaper and more durable metals.

- Improved Speed: Developments in machine technology that speed up printing.

- Software Enhancements: Better prediction of material properties and behavior.

Future Trends in Metal 3D Printing

Looking ahead, we might see:

- Increased Adoption: More industries will embrace metal 3D printing.

- Hybrid Machines: Combining additive and subtractive processes in one unit.

- Greater Customization: More opportunities for personalized products.

FAQs About 3D Printers That Print Metal

- What is the cost of a 3D printer that prints metal? The price varies greatly, typically starting from $50,000 and can go into millions depending on the complexity and scale.

- Can I use a metal 3D printer at home? Due to the cost, size, and safety requirements, metal 3D printers are not generally suitable for home use.

- What industries benefit most from metal 3D printing? Aerospace, automotive, and medical industries see the greatest benefits, due to the need for complex, customized, lightweight parts.

- How strong are the parts made with a 3D printer that prints metal? Metal 3D printed parts are comparable to those made by traditional manufacturing in terms of strength and durability.

- What is the future of metal 3D printing? The future is promising with advancements in technology, materials, and software that will continue to expand the capabilities and reduce costs.

Conclusion: The Expanding Horizon of Metal 3D Printing

As technology progresses, the possibilities for a 3d printer that prints metal continue to grow. These machines not only offer a glimpse into the future of manufacturing but also demonstrate how digital fabrication can be melded with traditional methods to create something truly revolutionary. Embracing this technology means stepping into a world of unlimited creative potential and innovation.